Bramac s.r.l. was founded in 1965 from the far-sighted mind of Masiero Bracalente who, in the years of the Fermo shoes business boom, decided to open a footwear machinery trading company in Montegranaro to serve the Italian and foreign market.

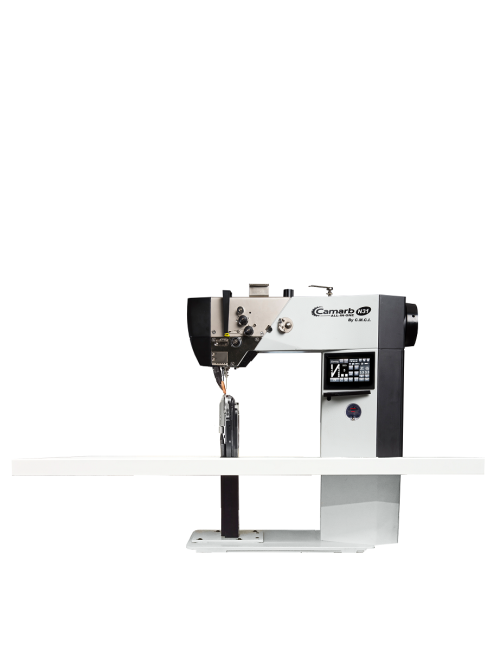

Over the years, the company has managed to expand customers, skills and turnover, becoming a leader in the wholesale sector of sewing machines for footwear, leather goods and the footwear industry at national and international level.

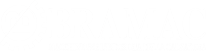

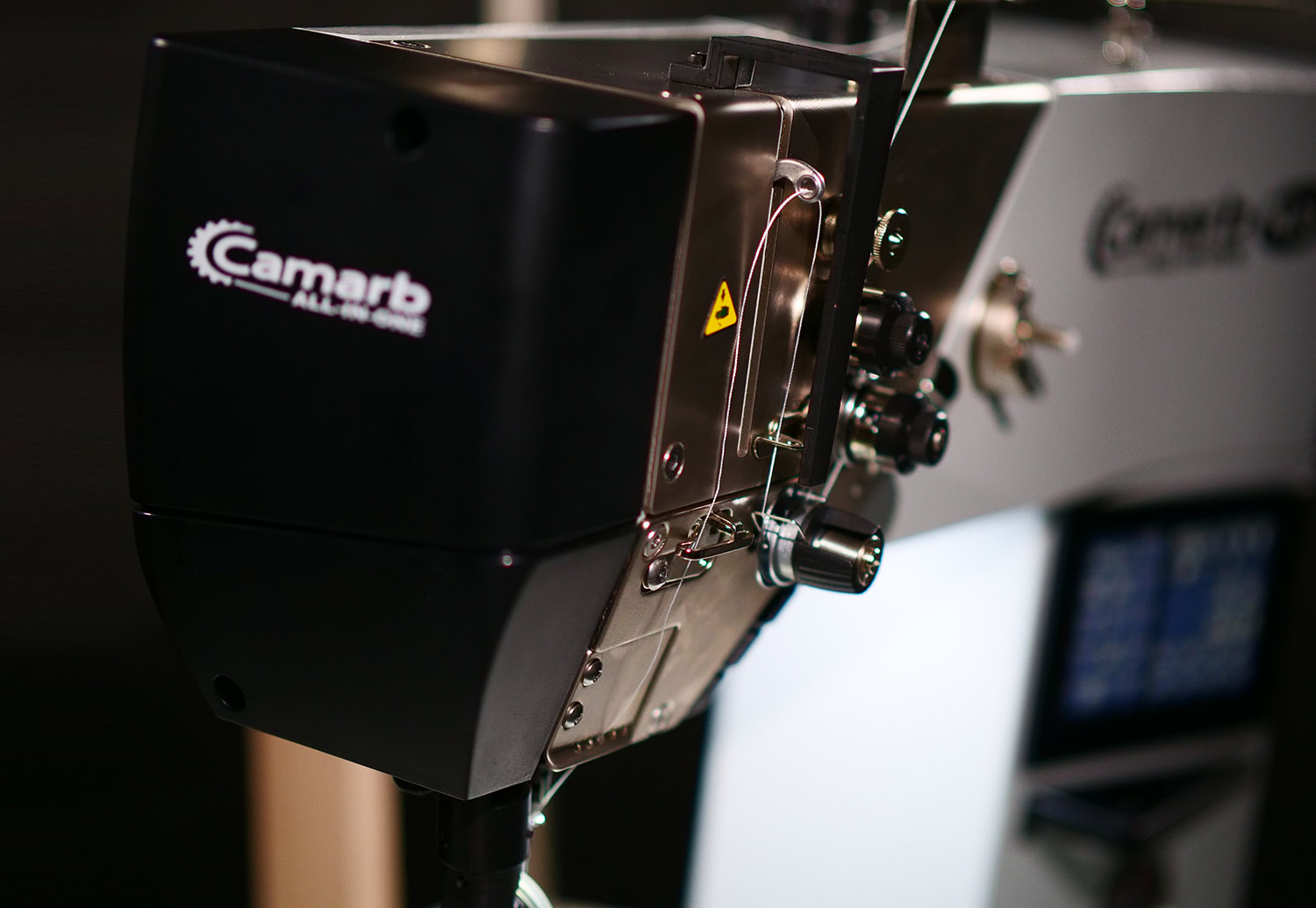

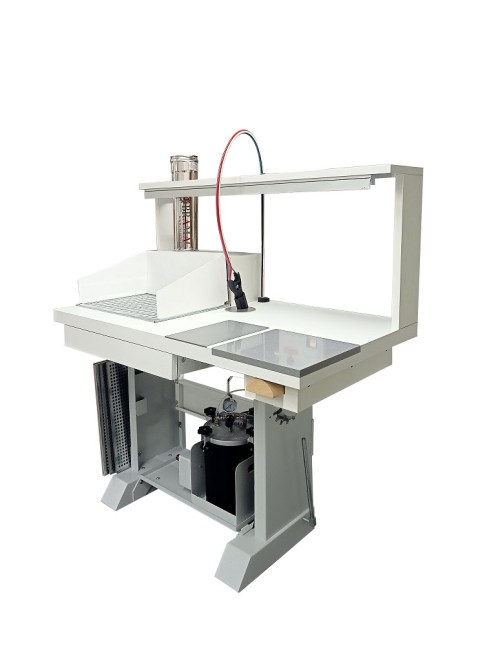

The main mission is to offer machinery adapted to the needs of customers, allowing them to obtain ever higher quality standards. Objective achieved thanks to a team of designers and automation engineers who make up the Bramac-Lab.

A division that aims to reinvent production processes and design new machinery suitable for the industry of the future. Bramac s.r.l. is able to design and install complete new generation production systems, as well as provide after-sales services, assistance and staff training, designed and defined for each individual customer, in Italy and abroad.