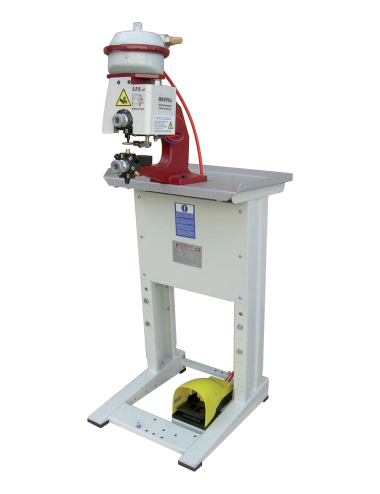

Tunnel di stiratura, invecchiamento, stabilizzazione e raffreddamento.

Questa macchina si differenzia dai normali forni di stiratura per i tempi prolungati di trattamento termico a temperature meno elevate

La scarpa o stivale, lentamente copia la forma lasciando il giusto tempo ai diversi tipi di materiale di modificarsi.

Al termine del processo di stiratura, la successiva camera di raffreddamento, fissa la tomaia e tutti i particolari sulla forma, in modo da renderla stabile anche dopo il successivo scalzamento.

Le regolazioni effettuabili sono: temperatura aria da 80° a 160°C, temperatura del vapore da 120 a 160 °C, percentuale di vapore da 0 a 100%, temperatura camera di raffreddamento da 5° a 15°C.