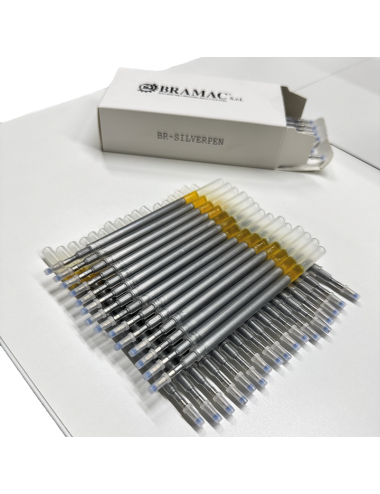

BR - SILVER PEN

The BR-SILVER PEN is Bramac’s new innovative pen, designed for leather marking, ideal for working on uppers and other leather goods. With its slim design and precise tip, it allows for clean, highly visible marks using silver ink.

The key feature of the BR-SILVER PEN is its washable and erasable ink. Simply use a little water and a cloth to easily remove the marks without damaging the leather surface. This makes the BR-SILVER PEN the perfect tool for working with valuable materials, ensuring precise work without the worry of permanent markings.