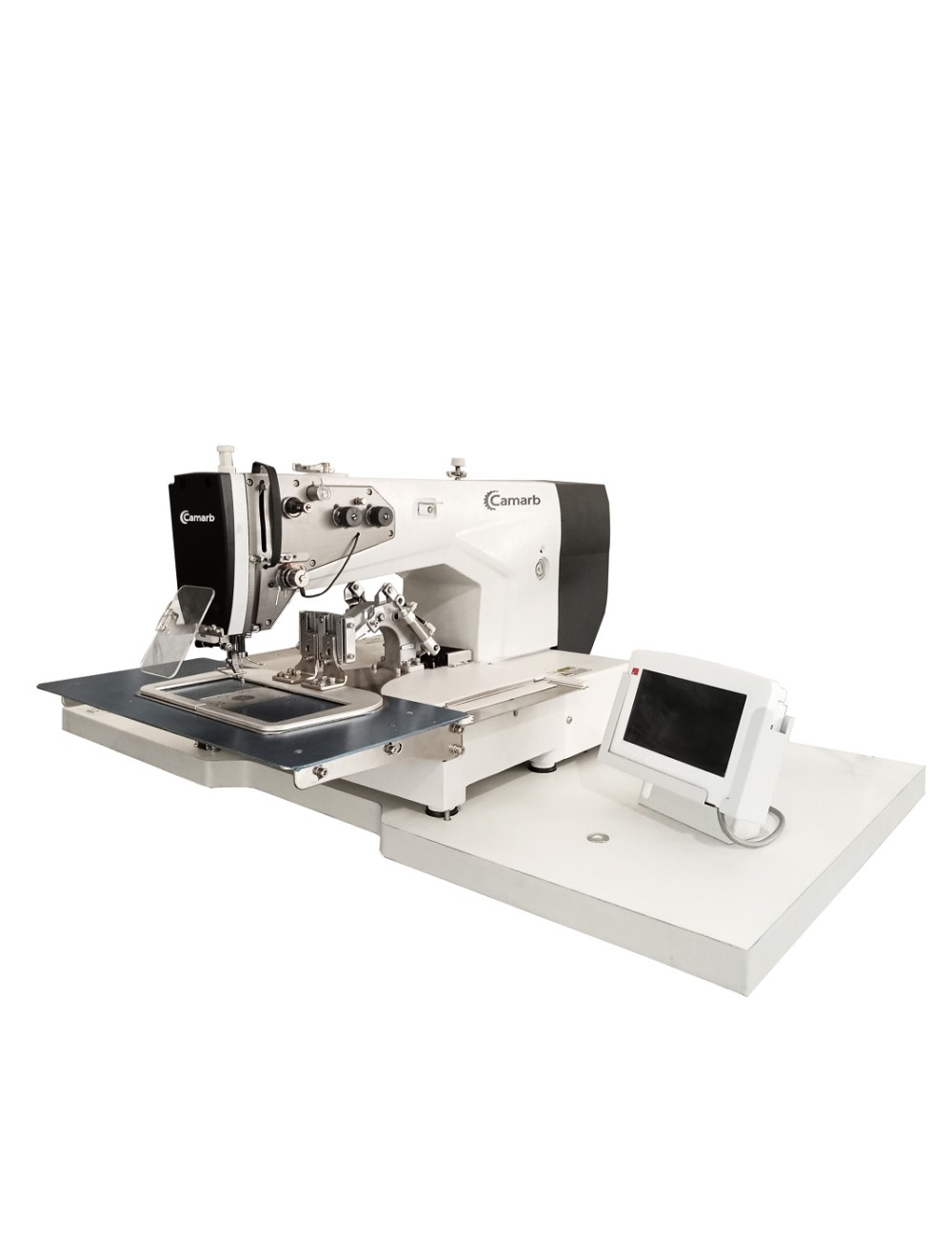

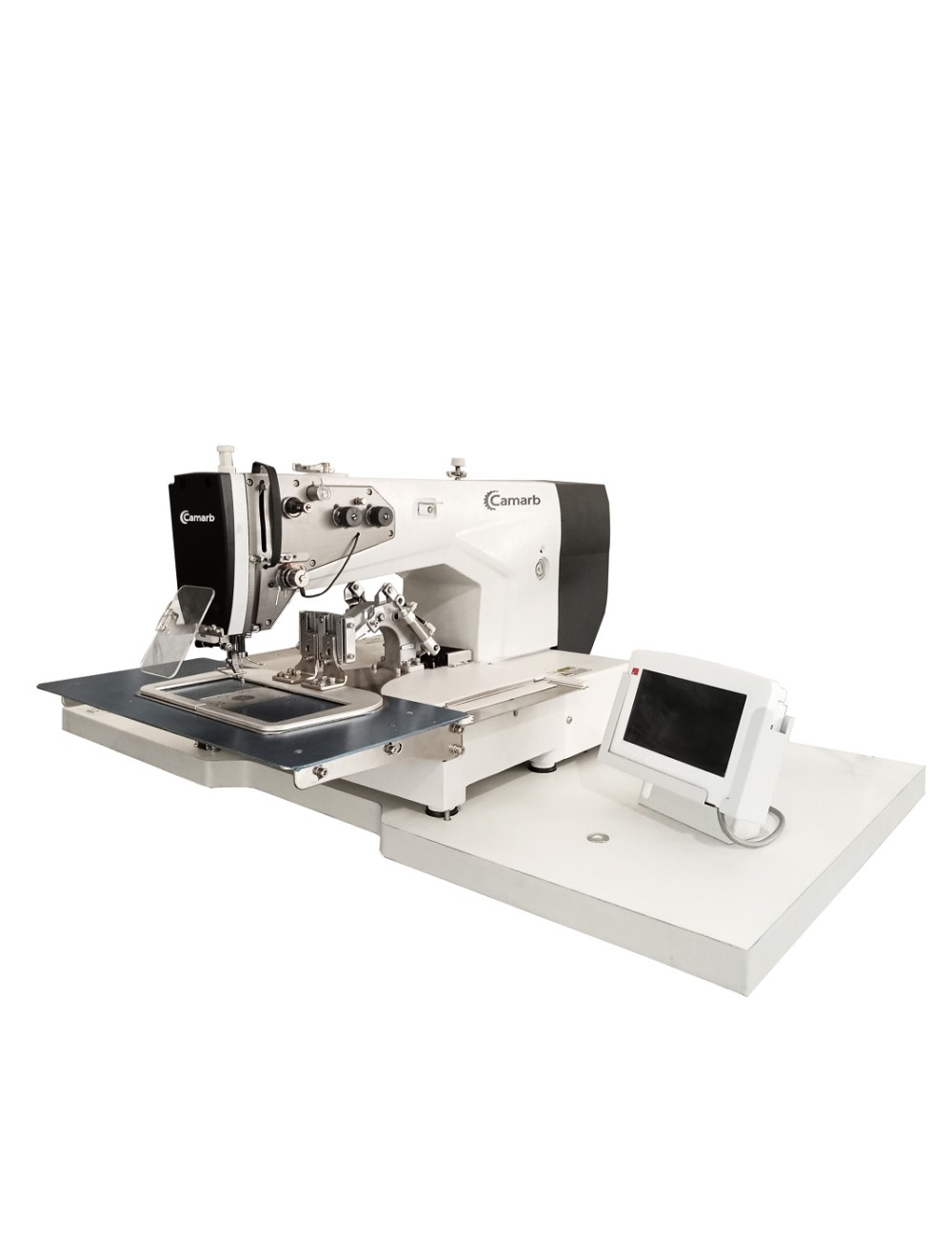

CAMARB N150-100

Single needle programmable pattern sewing machine:

- Equipped with thread trimmer

- Pneumatic presser foot lifter

- Electric backtracking

- Pneumatic pallet lifter

- Stepper motor with variable speed

Single needle programmable pattern sewing machine:

APPLICATION AREA

The N220-100 is used to work on man/woman apparel, denim, bags, leather, shoes and other applications.

The user can import his CAD drawing using a USB pendrive or various flash cards (CF, FD, SM, SD, etc…) in the machine system, that will convert it in a sewing set.

All the displaying, control and editing operations can be managed from a extractable touch screen.

PRODUCT ADVANTAGES

TECHNICAL DATA

Product |

CAMARB N150-100

CAMARB N150-100

|

Camarb N300-200

Camarb N300-200

|

Camarb N600-400

Camarb N600-400

|

Camarb N450-300

Camarb N450-300

|

Description |

Single needle programmable pattern sewing machine:

|

Single needle programmable pattern sewing machine:

|

Single needle programmable pattern sewing machine:

|

Single needle programmable pattern sewing machine:

|

Functions |

1 Needle | 1 Needle | 1 Needle | 1 Needle |

Dimensions |

116x107x125 cm | 140x116x120 cm | 180x140x140 cm | 180x140x140 cm |

Weight |

108 Kg | 160 kg | 180 Kg | 180 Kg |

|

|

|

|

|

Single needle programmable pattern sewing machine:

Single needle programmable pattern sewing machine:

Single needle programmable pattern sewing machine:

Single needle programmable pattern sewing machine:

Single needle programmable pattern sewing machine: